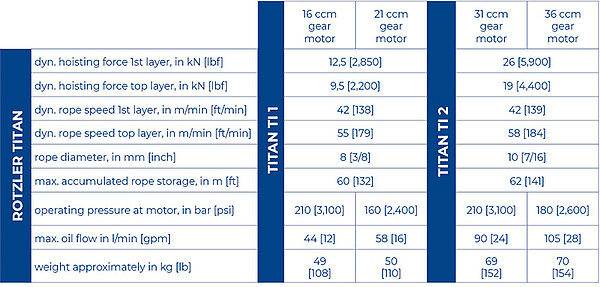

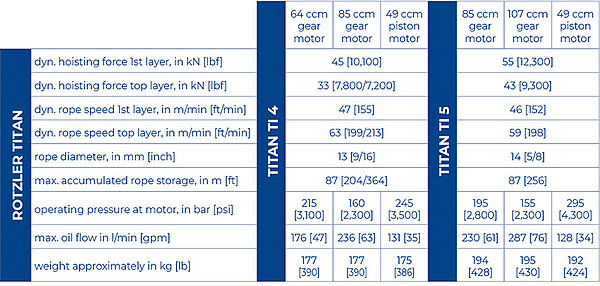

ROTZLER TITAN TI - Hydraulic hoisting winch

Hoisting force range 12,5 bis 55,0 kN

Good reasons for ROTZLER TITAN hoisting winches

- Compact and robust design

- Superior reliability

- Highest safety standards

- Precise load positioning

- Highly configurable

- Improved performance

- Unique ROTZLER hydraulic motor

- Easy to maintain

Standard features of ROTZLER TITAN

- high quality, two-step planetary gearbox

- high-performance hydraulic motor

- overrunning clutch for precise load control and positioning

- sensitive brake with static and dynamic brake functions for gentle lowering of loads

- high-quality coating to protect against seawater

- contact surfaces made of corrosion-proof steel

- ventilation valve made of stainless steel

- graphite brake discs

ROTZLER TITAN - available options

- large drum

- grooved drum

- pressure roller

- rope end control

- load sensing system MCD

- sea water protection

- emergency brake release

- brake test valve

drum

drum, pressure roller and MCD

Applications for ROTZLER TITAN hoisting winches:

Brochures and Information

Further product information and brochures for download at the Infopoint.

© Copyright ROTZLER HOLDING GmbH + Co. KG

Deutsch

Deutsch English

English